Lacks and Toyota. Together creating a symmetry of design and efficiency.

An exercise in inspiration

Lacks was approached by Toyota about designing six unique wheels across two of their all-new vehicle models, Sienna and Tacoma. By combining the versatility of Lacks electroplating finish technologies and the flexibility of Chromtec®, Toyota engineers were able to streamline their testing and validation processes and increase creative freedom for each model, while accentuating trim level differentiation.

Empowered by Lacks proprietary finish décor technologies’ ability to layer chrome, color and texture seamlessly, the Toyota design team was able to create unique looks for each trim level without the additional investment required to validate a new backbone for each.

TOYOTA SIENNA

From an 18″ wheel with multiple designs to a single 20″ design with multiple finishes, Lacks finish technologies enhanced model differentiation while yielding time and cost savings across a complex Sienna program. Each wheel size utilized a common backbone, providing savings on tooling costs.

- Two lightweighted backbones

- Various levels of plating, Selective Spinelle™ and Tessera® finishes on a single piece

- Trim level differentiation

Awarding Innovative Thinking

These two prestigious awards are a testament to the level of innovation Lacks brings to every project. Lacks light-weighting technology and program development capabilities for the 2021 Toyota Sienna yielded results that exceeded expectations and garnered us both the 2021 Toyota’s Excellent Technology & Development Award, and the 2022 Altair Enlighten Award’s Sustainability for Product.

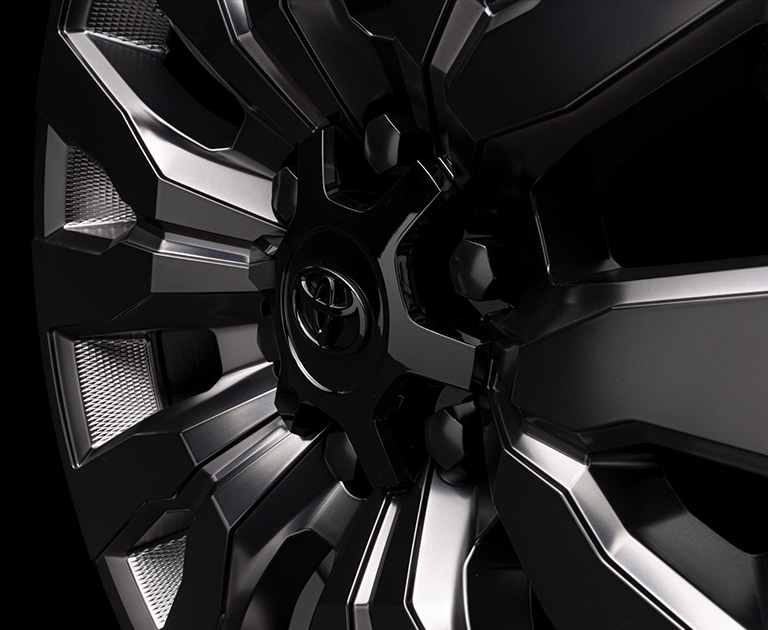

TOYOTA TACOMA

For the Toyota Tacoma, Lacks created a single design with multiple finishes, which provided savings on tooling costs. The lightweighted backbone and high-definition 3-D Tessara® textures utilized multiple gloss levels and Spinelle™ colors to get more value from the same design while enabling engineers to meet vehicle fuel economy targets.

- One design with multiple wheel finishes

- Common lightweighted backbone

- Tool cost savings by utilizing same design

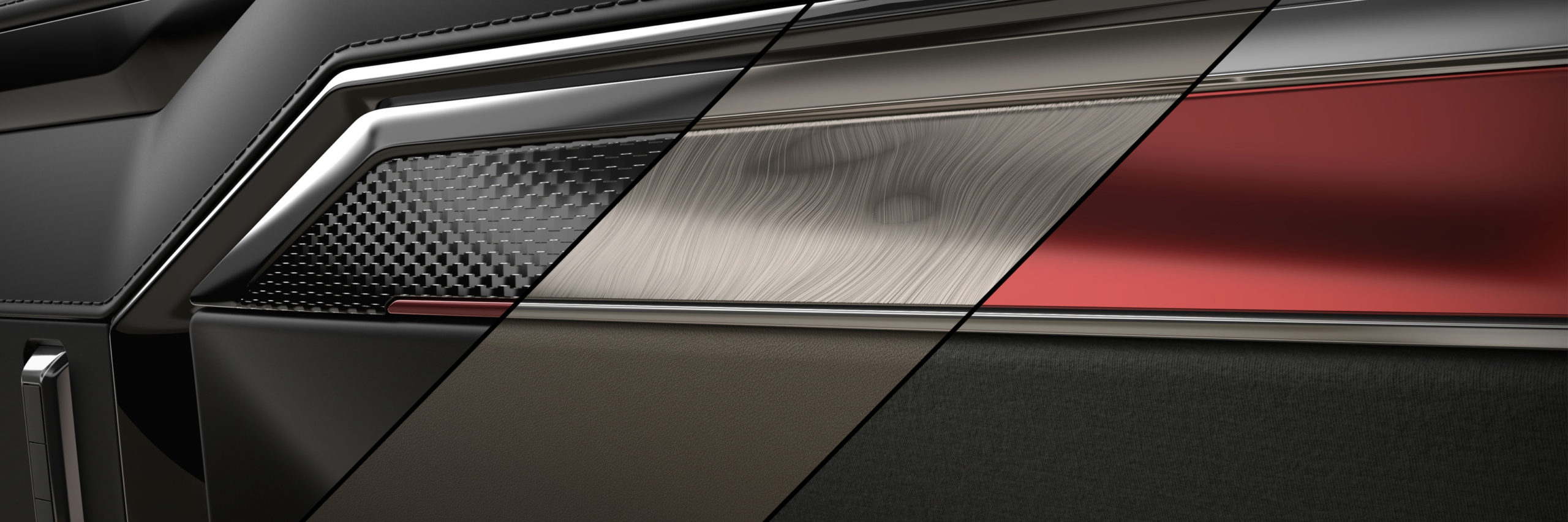

ONE SOLUTION. COUNTLESS POSSIBILITIES.

The versatility of the composite design surface of Chromtec® provided the Toyota design studio with a blank canvas and access to Lacks’ full collection of gloss levels, rich colors and high-definition textures. By layering chrome, color and texture the design team was able to create unique looks for each trim level. Chromtec® also provided designers with the flexibility of creating new design faces, while saving engineering from needing to validate a new backbone.

The harmonization between our finishes allowed the Toyota design team to add a touch of customization to each wheel.

Each program features its own common backbones with unique Chromtec® composite design, allowing for a range of styles with no extra validating or tooling.

By utilizing the same tooling and validated backbone, Toyota can update finishes to get greater revenue for future models and limited production “buzz models.”

LACKS FINISH TECHNOLOGIES CREATE A WORLD OF STUNNING POSSIBILITIES

The innovation Lacks has brought to the world of finish technologies expanded Toyota designers’ creative freedom beyond what is obtainable with traditional wheel design and finish options.

- Tessera® texture technology allows for the engineering of highly-detailed 3-D textures onto a component’s surface

- Spinelle™ metal finishes provide endless, rich color possibilities, including multiple options on a single piece with Selective Spinelle™ technology

- The ability to create multiple textures and colors combinations for nearly infinite trim and model differentiation options

ROLLING IN VERSATILITY

Lacks has long been an industry leader in décor finish technologies, providing designers extraordinary possibilities to pursue. We continually deliver improvements in weight reduction and advanced 3-D texturing capabilities.

Wheel Trim Systems

Explore what’s possible

Try our Finish Selector to experience Lacks finishes on a variety of materials.

Finish Selector