For over 60 years, Lacks has developed millions of décor solutions that balance art and science—without compromise. Through our innovations in polymer chemistry, manufacturing, and testing, Lacks Carbon Fiber™ is proud to present our 2-piece carbon fiber wheel that can achieve the performance you are looking for with the freedom to create distinctive designs.

The 2-piece architecture and deep-lip design deliver the performance enhancements and aesthetic appeal of a carbon fiber rim with the design flexibility of a forged alloy disc. A single, validated carbon fiber rim can accommodate infinite design geometries and finishes, allowing designers the freedom to create brand, vehicle, and trim level differentiation.

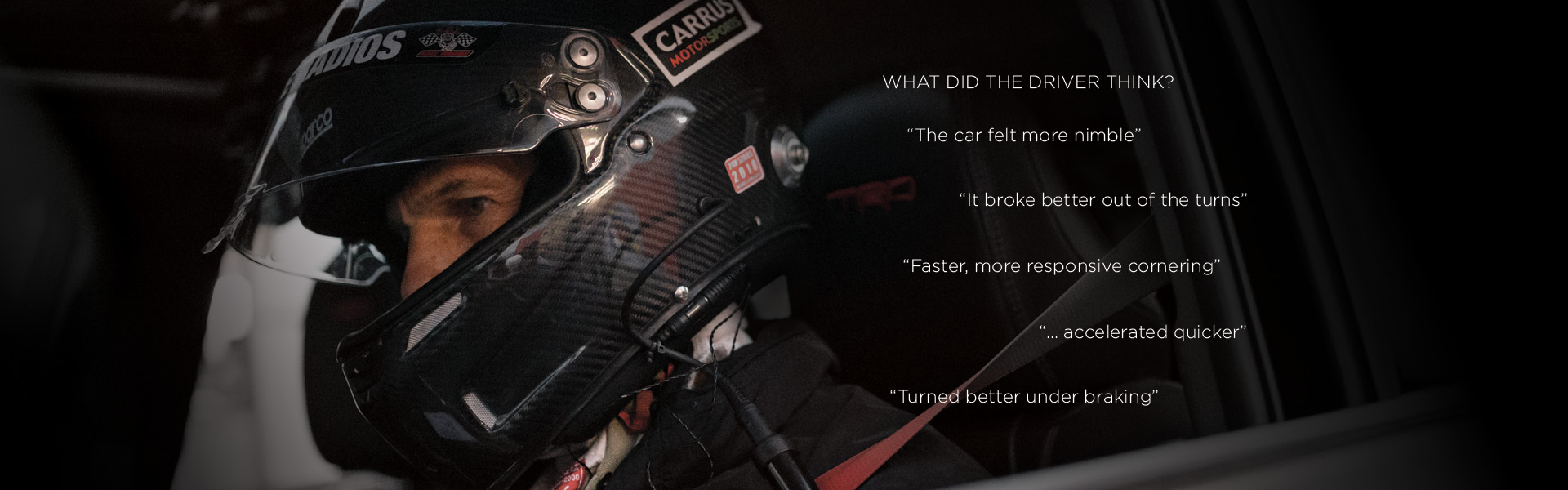

Get a better driving experience with improvements in weight reduction, ride and handling, energy efficiency, and noise damping. Reductions in unsprung mass and rotational inertia translate to a precision driving experience with faster acceleration/deceleration and more responsive handling with fewer high-frequency vibrations.

Our carbon fiber barrels use our proprietary thermoset resin combinations that are UV stable with high glass transition temperature. Both weave and resins are customized to individual vehicle requirements. The forged 6061-T6-aluminum disc is CNC machined for excellent strength-to-weight ratio and connected with corrosion-resistant titanium bolts.

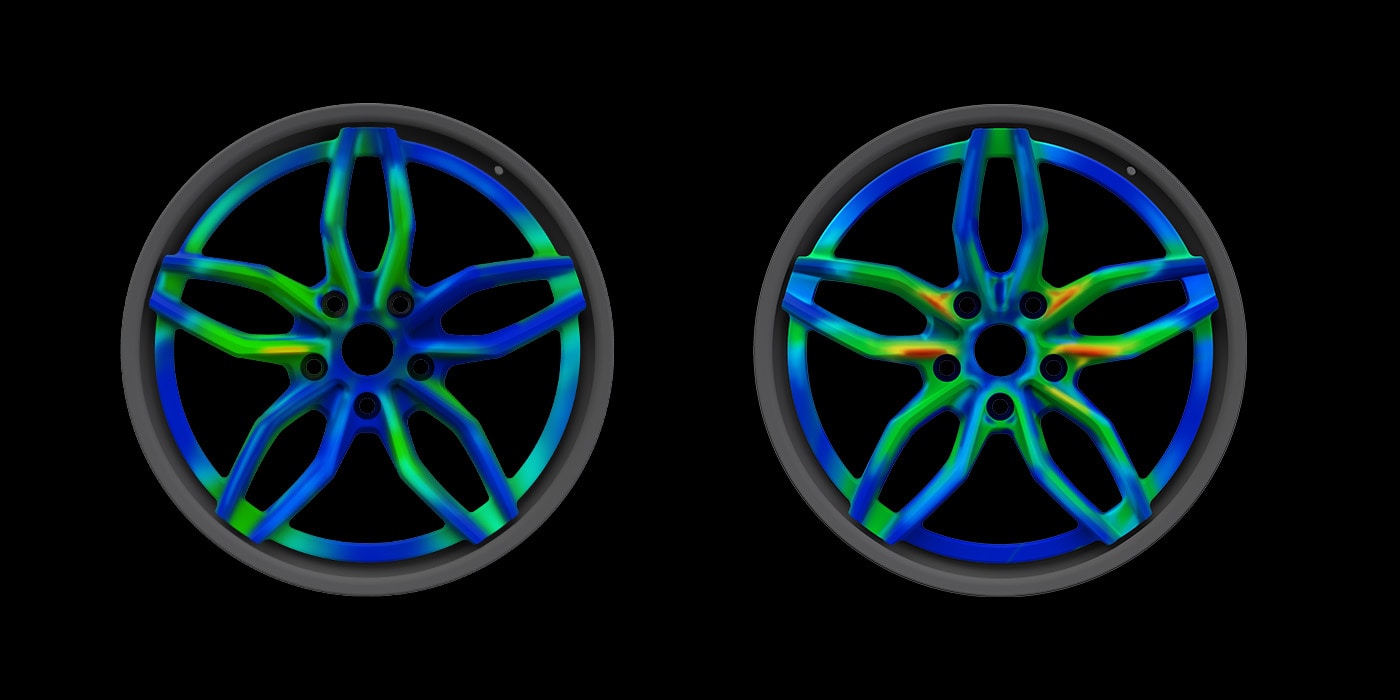

Lacks in-house and independent testing puts our wheels through their paces in tests, simulating real-world driving scenarios like curbs and potholes, as well as intense environmental, temperature, UV, and chemical exposure.

Our proprietary layup and molding process, creates a distinct carbon fiber pattern and reduces up-front tooling costs. Our automated process was engineered to allow for the reuse of common rim manufacturing equipment. Our production process is flexible and scalable with fast time to market and short cycle times.

Lacks has one of the most advanced in-house testing facilities in the industry, capable of environmental and chemical testing, as well as FEA. We certify our wheels for strength, performance and material durability to both U.S. and European OEM and aftermarket standards.

Don’t take our word for it—in real-world testing, the advantages of Lacks Carbon Fiber™ wheels gave drivers something to talk about.

To create the world's most advanced carbon fiber wheel, we had to re-engineer the entire manufacturing process. Our design, fabrication, assembly, and manufacturing patents don't just set the bar—they redefine it.

Lacks is continually searching for new ways to help our OEM partners expand their imaginations. Our featured projects showcase how our team of experts turned our clients’ challenges into admired or awarded applications.

Lacks Carbon Fiber™ partnered with Dodge to unleash the world’s quickest production car. Record-breaking speed demands record-breaking innovation.