Launching

We were proud to partner with Dodge to debut our 2-piece carbon fiber wheel on the 2023 Challenger SRT Demon C170, the quickest production car ever created. Our lightweight, high-performance carbon fiber wheels were designed specifically to handle the extreme temperature, impact, and performance demands needed to launch this Demon into the record books.

Launching

Impact

Our 2-piece architecture gave Dodge the perfect blend of style and performance. With its deep lip design and large weave pattern, our carbon fiber barrels have an unmistakable aesthetic of speed. Paired with a CNC-machined 6061-T6 forged aluminum center, Lacks Carbon Fiber Wheels™ brought Dodge’s vision to life with the attitude the Demon demanded.

To Move

Our lightweight carbon fiber wheels put the weight exactly where it matters most, reducing unsprung mass and rotational inertia. Our design helped Dodge hit its performance targets with the strength and durability to handle the 18,000 pounds of tractive force unleashed by the 1025-horsepower Demon.

31.4 lbs weight reduction vs traditional aluminum wheels.

Reductions in unsprung mass deliver a more consistent tire load and more responsive handling.

61% reduction in PMOI because weight reduction at the rim has an exponentially higher impact on MOI than at the hub.

Carbon fiber delivers greater stiffness than aluminum, cutting vibration, and noise while increasing strength.

Our patented multi-resin manufacturing process can strategically place purpose-engineered materials throughout the wheel structure for consistent, high-performance results. Our in-house resins are built to resist high temperatures, absorb the hits, and provide UV stability. Every detail matters when you’re chasing the edge.

High Tg Resin

High glass transition temperature resin along inside of the wheel to withstand high brake temperatures.

High G1c Resin

High toughness resin along rim and tire seats provide improved impact performance.

Custom Surfaces

UV-stable surface ply won’t yellow and Dodge-custom anti-slip coating eliminated tire slip.

Proven.

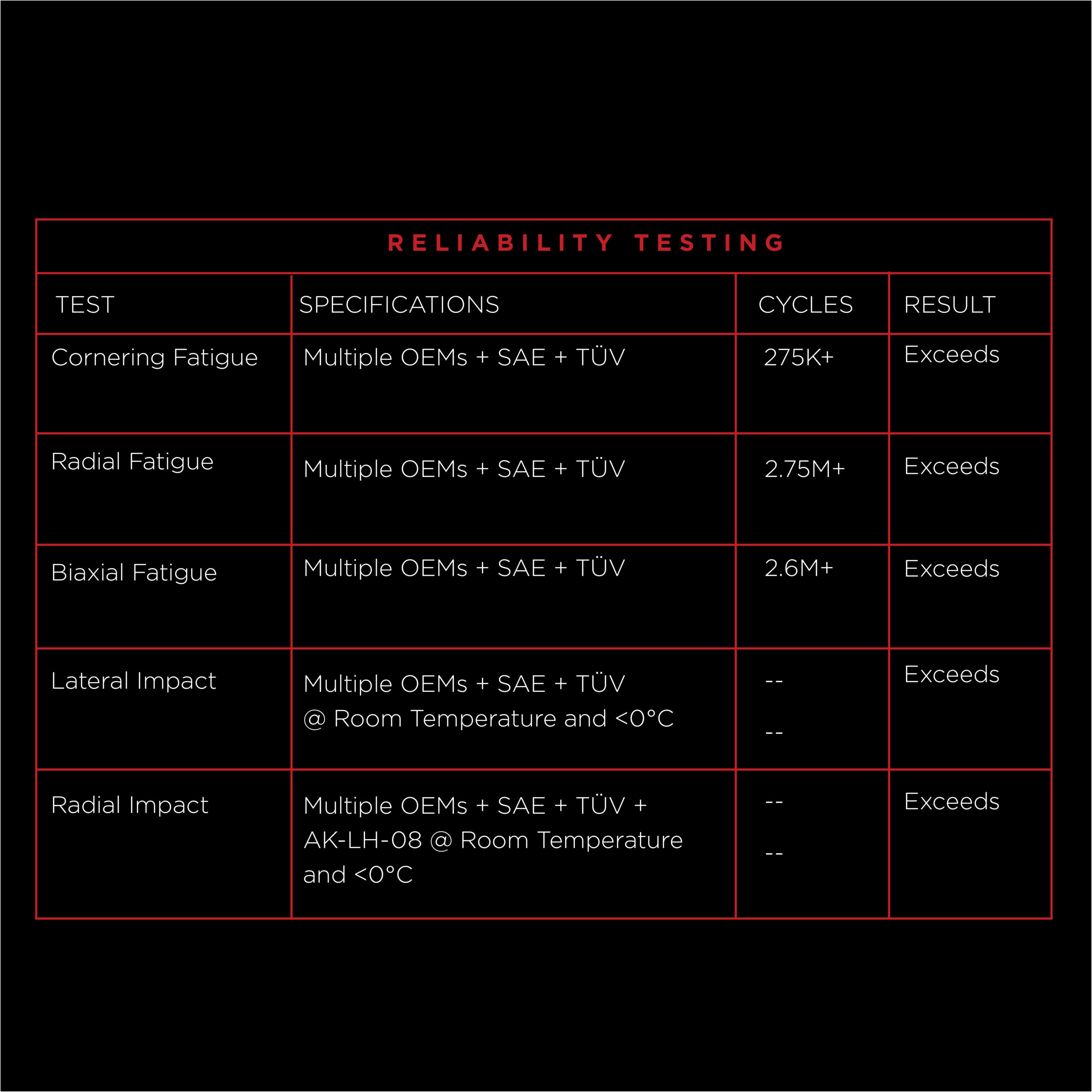

We went beyond the standard testing playbook to ensure our wheels could handle the drag strip’s intense stress, searing heat, and high torque. Our testing and manufacturing teams engineered the Demon’s carbon fiber wheel to meet every demand Dodge threw at it. Our comprehensive testing exceeded SAE protocols for impact and fatigue, as well as custom-designed tests for water intrusion and thermal conditioning to ensure this wheel was ready for the starting line.

Nothing

Over 10 months, Lacks partnered closely with Dodge to hit every milestone and deliver over 3,300 purpose-built wheels. Our scalable manufacturing and advanced carbon fiber solutions helped Dodge push performance limits without sacrificing style and attitude. Today, we continue to set new standards in the industry, proving how our expertise in lightweight materials can elevate the entire look and feel of the driving experience.