Light.

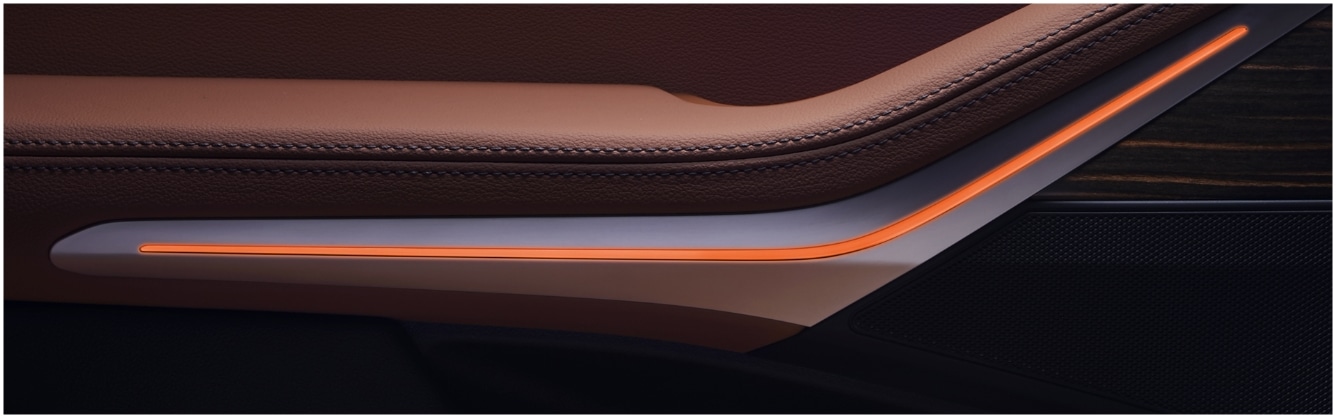

When designing the new X5 interior, BMW needed to integrate their interior LED lighting design to accommodate packaging constraints while maintaining engineering tolerances. Through our collaboration, a new 2-shot, 1-piece backlit design and manufacturing approach solved the packaging space challenges while creating an array of visually appealing parts with additional assembly benefits.

Light.

+ Manufacturing Excellence

The collaboration with BMW in the early stages helped us to use our extensive experience in resin selection, injection molding, and advanced plating techniques to harmonize the design of multiple interior components.

For the X5 Interior, a more sophisticated 2-shot process was used to mold lighting and trim pieces in one part. Innovations in material bonding resulted in a clean joint line with full adhesion between platable and non-platable substrates.

LIGHT + COLOR

Collaborating with resin suppliers we established the optimal resin for light and color transfer while achieving sufficient opacity to mask the lighting engines themselves.

BREAKING THE MOLD

Our manufacturing approach allowed for customizable direct and indirect lighting on the same piece.

THE PERFECT FINISH

With the inclusion of a lighting element, surface finishes uphold the highest standards of quality and fidelity.

MOOD

EXPERTISE

Lacks capability with complex interior trim programs allows us to work collaboratively with our

partners to achieve design solutions without compromise.

See how the full array of Lacks interior solutions can revolutionize your design potential.